Mohammed M. S. El-Kholany

Hybrid ASP-based multi-objective scheduling of semiconductor manufacturing processes (Extended version)

Jul 28, 2023Abstract:Modern semiconductor manufacturing involves intricate production processes consisting of hundreds of operations, which can take several months from lot release to completion. The high-tech machines used in these processes are diverse, operate on individual wafers, lots, or batches in multiple stages, and necessitate product-specific setups and specialized maintenance procedures. This situation is different from traditional job-shop scheduling scenarios, which have less complex production processes and machines, and mainly focus on solving highly combinatorial but abstract scheduling problems. In this work, we address the scheduling of realistic semiconductor manufacturing processes by modeling their specific requirements using hybrid Answer Set Programming with difference logic, incorporating flexible machine processing, setup, batching and maintenance operations. Unlike existing methods that schedule semiconductor manufacturing processes locally with greedy heuristics or by independently optimizing specific machine group allocations, we examine the potentials of large-scale scheduling subject to multiple optimization objectives.

Problem Decomposition and Multi-shot ASP Solving for Job-shop Scheduling

May 23, 2022

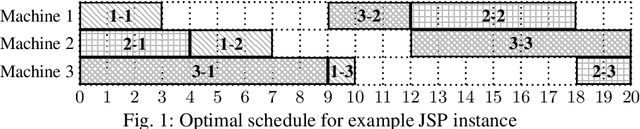

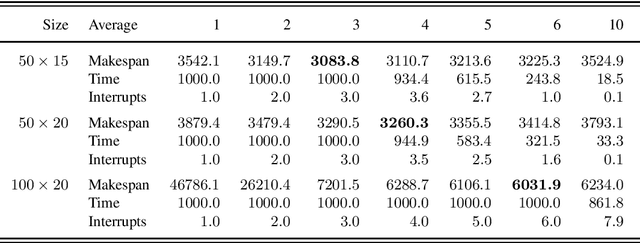

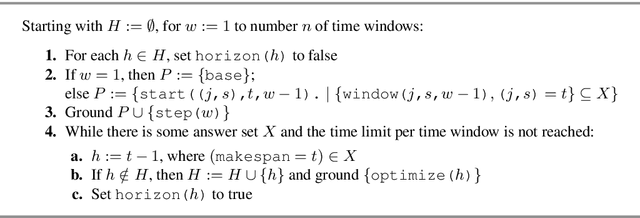

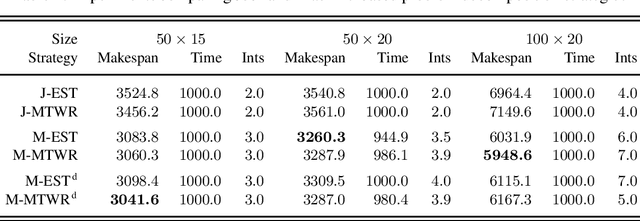

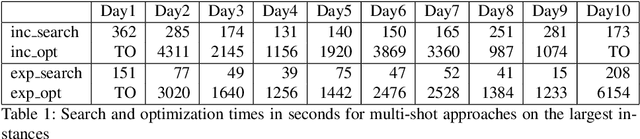

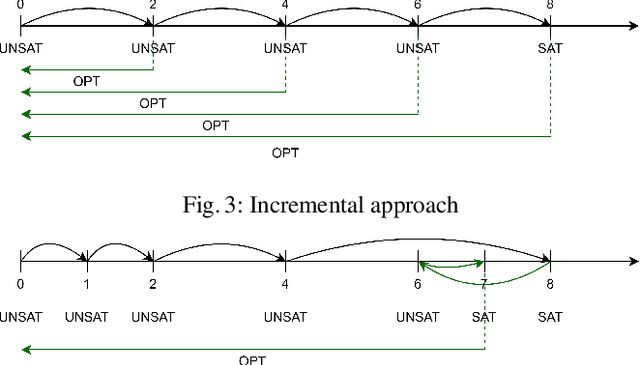

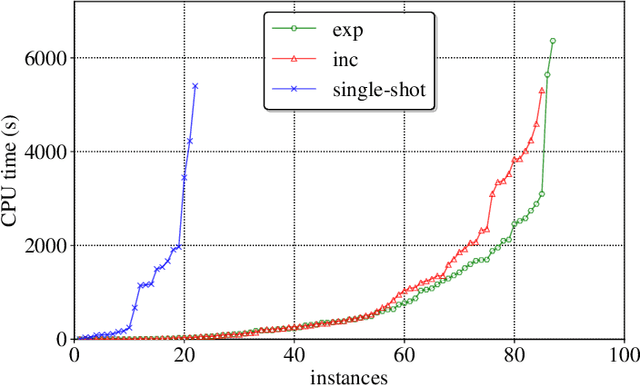

Abstract:The Job-shop Scheduling Problem (JSP) is a well-known and challenging combinatorial optimization problem in which tasks sharing a machine are to be arranged in a sequence such that encompassing jobs can be completed as early as possible. In this paper, we propose problem decomposition into time windows whose operations can be successively scheduled and optimized by means of multi-shot Answer Set Programming (ASP) solving. Decomposition aims to split highly complex scheduling tasks into better manageable sub-problems with a balanced number of operations so that good quality or even optimal partial solutions can be reliably found in a small fraction of runtime. Problem decomposition must respect the precedence of operations within their jobs and partial schedules optimized by time windows should yield better global solutions than obtainable in similar runtime on the entire instance. We devise and investigate a variety of decomposition strategies in terms of the number and size of time windows as well as heuristics for choosing their operations. Moreover, we incorporate time window overlapping and compression techniques into the iterative scheduling process to counteract window-wise optimization limitations restricted to partial schedules. Our experiments on JSP benchmark sets of several sizes show that successive optimization by multi-shot ASP solving leads to substantially better schedules within the runtime limit than global optimization on the full problem, where the gap increases with the number of operations to schedule. While the obtained solution quality still remains behind a state-of-the-art Constraint Programming system, our multi-shot solving approach comes closer the larger the instance size, demonstrating good scalability by problem decomposition.

Solving a Multi-resource Partial-ordering Flexible Variant of the Job-shop Scheduling Problem with Hybrid ASP

Jan 26, 2021

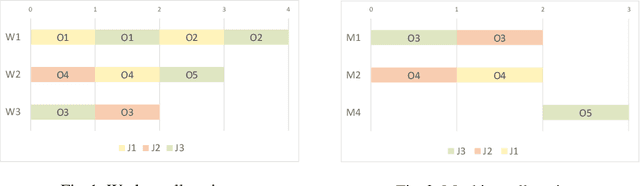

Abstract:Many complex activities of production cycles, such as quality control or fault analysis, require highly experienced specialists to perform various operations on (semi)finished products using different tools. In practical scenarios, the selection of a next operation is complicated, since each expert has only a local view on the total set of operations to be performed. As a result, decisions made by the specialists are suboptimal and might cause significant costs. In this paper, we consider a Multi-resource Partial-ordering Flexible Job-shop Scheduling (MPF-JSS) problem where partially-ordered sequences of operations must be scheduled on multiple required resources, such as tools and specialists. The resources are flexible and can perform one or more operations depending on their properties. The problem is modeled using Answer Set Programming (ASP) in which the time assignments are efficiently done using Difference Logic. Moreover, we suggest two multi-shot solving strategies aiming at the identification of the time bounds allowing for a solution of the schedule optimization problem. Experiments conducted on a set of instances extracted from a medium-sized semiconductor fault analysis lab indicate that our approach can find schedules for 87 out of 91 considered real-world instances.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge