Mehrisadat Makki Alamdari

A New Architecture for Energy Efficient Fault Detection Using Energy Harvesters

Feb 21, 2024

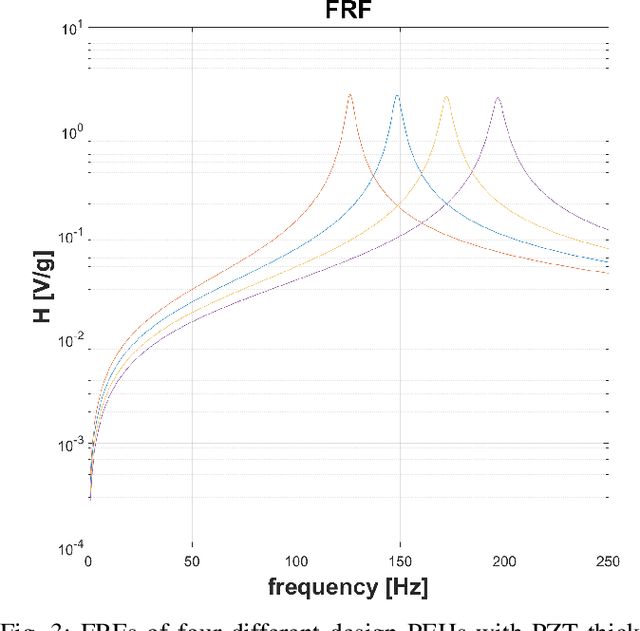

Abstract:The current battery-powered fault detection system for vibration monitoring has a rather limited lifetime. This is because the high-frequency sampling (typically tens of kilo-Hertz) required for vibration monitoring results in high energy consumption in both the analog-to-digital (ADC) converter and wireless transmissions. This paper proposes a new fault detection architecture that can significantly reduce the energy consumption of the ADC and wireless transmission. Our inspiration for the new architecture is based on the observation that the many tens of thousand of data samples collected for fault detection are ultimately transformed into a small number of features. If we can generate these features directly without high frequency sampling, then we can avoid the the energy cost for ADC and wireless transmissions. We propose to use piezoelectric energy harvesters (which can be designed to have different frequency responses) and integrators to obtain these features in an energy-efficient manner. By using a publicly available data set for ball bearing fault detection (which was originally sampled at 51.2kHz) and piezoelectric energy harvester models, we can produce features, which when sampled at 0.33Hz, give a fault detection accuracy of 89% while reducing the sampling requirement by 4 orders-of-magnitude.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge