Kilian Wasmer

Reinforcement Learning on Reconfigurable Hardware: Overcoming Material Variability in Laser Material Processing

Jan 31, 2025

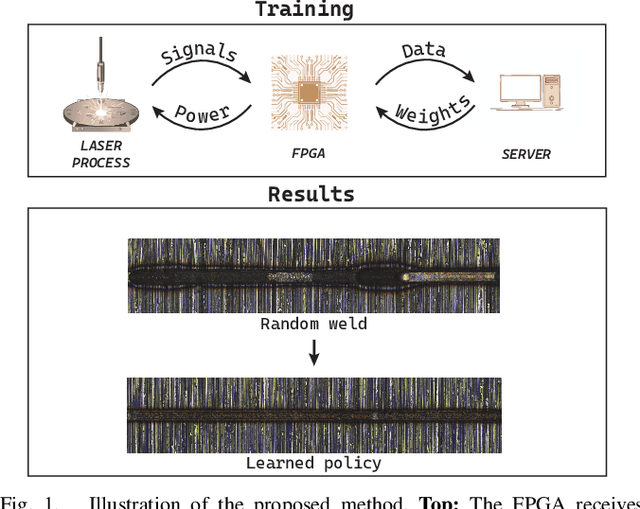

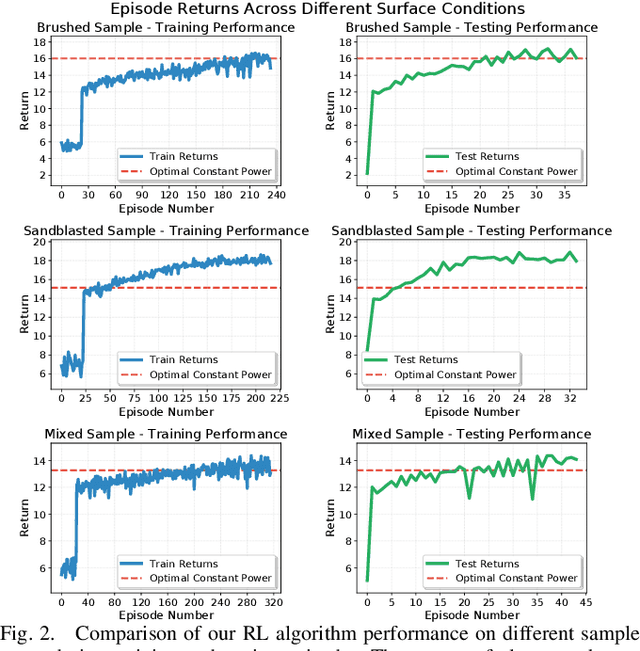

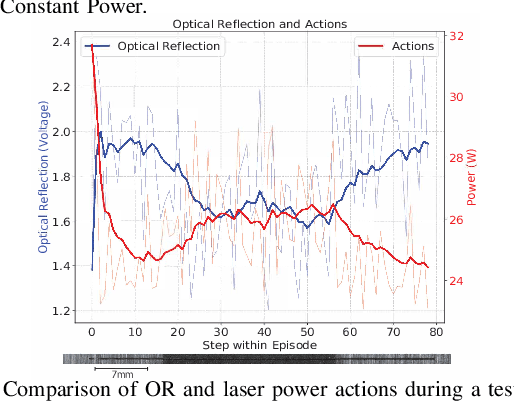

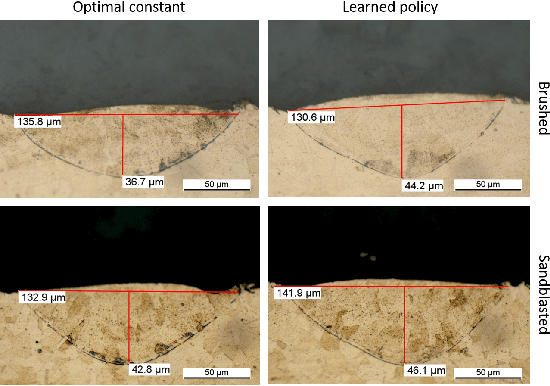

Abstract:Ensuring consistent processing quality is challenging in laser processes due to varying material properties and surface conditions. Although some approaches have shown promise in solving this problem via automation, they often rely on predetermined targets or are limited to simulated environments. To address these shortcomings, we propose a novel real-time reinforcement learning approach for laser process control, implemented on a Field Programmable Gate Array to achieve real-time execution. Our experimental results from laser welding tests on stainless steel samples with a range of surface roughnesses validated the method's ability to adapt autonomously, without relying on reward engineering or prior setup information. Specifically, the algorithm learned the correct power profile for each unique surface characteristic, demonstrating significant improvements over hand-engineered optimal constant power strategies -- up to 23% better performance on rougher surfaces and 7% on mixed surfaces. This approach represents a significant advancement in automating and optimizing laser processes, with potential applications across multiple industries.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge