Karsten Mueller

XAI-guided Insulator Anomaly Detection for Imbalanced Datasets

Sep 25, 2024

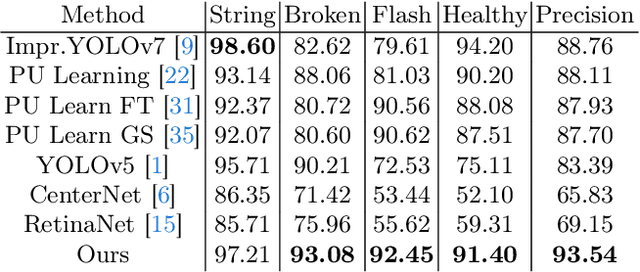

Abstract:Power grids serve as a vital component in numerous industries, seamlessly delivering electrical energy to industrial processes and technologies, making their safe and reliable operation indispensable. However, powerlines can be hard to inspect due to difficult terrain or harsh climatic conditions. Therefore, unmanned aerial vehicles are increasingly deployed to inspect powerlines, resulting in a substantial stream of visual data which requires swift and accurate processing. Deep learning methods have become widely popular for this task, proving to be a valuable asset in fault detection. In particular, the detection of insulator defects is crucial for predicting powerline failures, since their malfunction can lead to transmission disruptions. It is therefore of great interest to continuously maintain and rigorously inspect insulator components. In this work we propose a novel pipeline to tackle this task. We utilize state-of-the-art object detection to detect and subsequently classify individual insulator anomalies. Our approach addresses dataset challenges such as imbalance and motion-blurred images through a fine-tuning methodology which allows us to alter the classification focus of the model by increasing the classification accuracy of anomalous insulators. In addition, we employ explainable-AI tools for precise localization and explanation of anomalies. This proposed method contributes to the field of anomaly detection, particularly vision-based industrial inspection and predictive maintenance. We significantly improve defect detection accuracy by up to 13%, while also offering a detailed analysis of model mis-classifications and localization quality, showcasing the potential of our method on real-world data.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge