Karl G. Kempf

An Odds Ratio Based Inference Engine

Mar 27, 2013

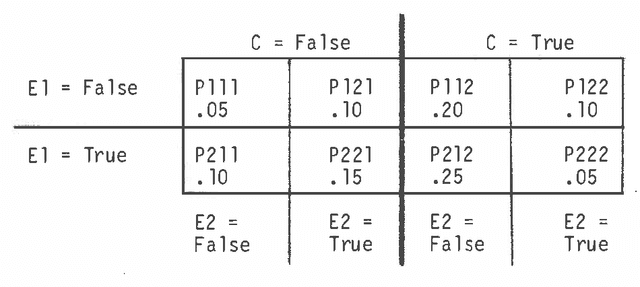

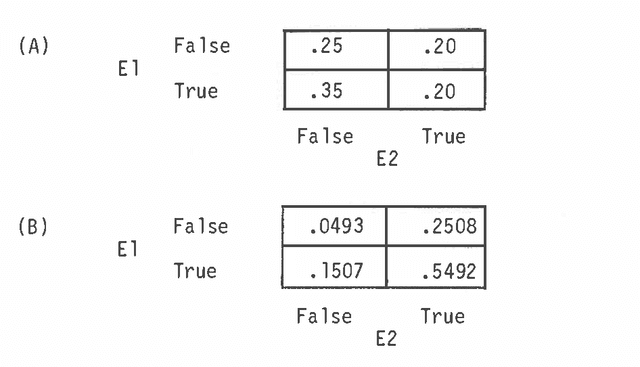

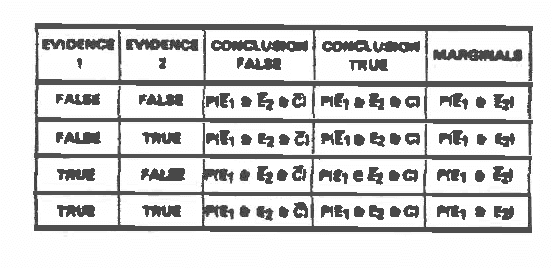

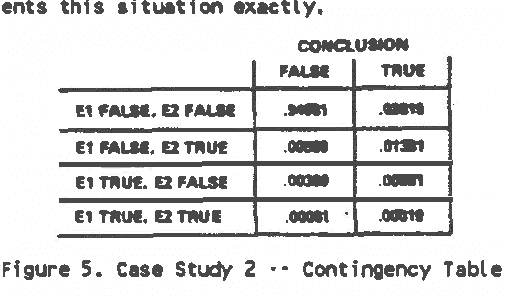

Abstract:Expert systems applications that involve uncertain inference can be represented by a multidimensional contingency table. These tables offer a general approach to inferring with uncertain evidence, because they can embody any form of association between any number of pieces of evidence and conclusions. (Simpler models may be required, however, if the number of pieces of evidence bearing on a conclusion is large.) This paper presents a method of using these tables to make uncertain inferences without assumptions of conditional independence among pieces of evidence or heuristic combining rules. As evidence is accumulated, new joint probabilities are calculated so as to maintain any dependencies among the pieces of evidence that are found in the contingency table. The new conditional probability of the conclusion is then calculated directly from these new joint probabilities and the conditional probabilities in the contingency table.

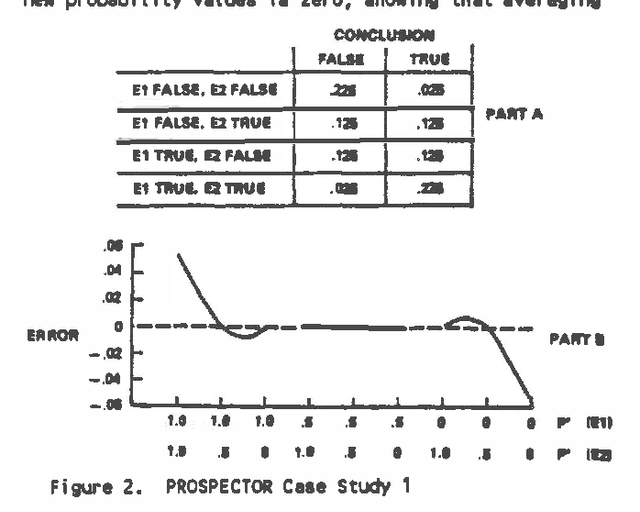

Evaluation of Uncertain Inference Models I: PROSPECTOR

Mar 27, 2013

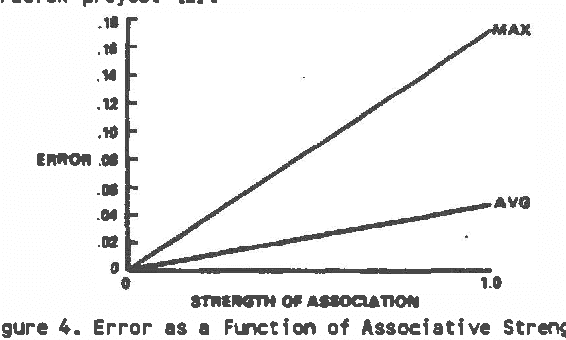

Abstract:This paper examines the accuracy of the PROSPECTOR model for uncertain reasoning. PROSPECTOR's solutions for a large number of computer-generated inference networks were compared to those obtained from probability theory and minimum cross-entropy calculations. PROSPECTOR's answers were generally accurate for a restricted subset of problems that are consistent with its assumptions. However, even within this subset, we identified conditions under which PROSPECTOR's performance deteriorates.

Planning, Scheduling, and Uncertainty in the Sequence of Future Events

Mar 27, 2013Abstract:Scheduling in the factory setting is compounded by computational complexity and temporal uncertainty. Together, these two factors guarantee that the process of constructing an optimal schedule will be costly and the chances of executing that schedule will be slight. Temporal uncertainty in the task execution time can be offset by several methods: eliminate uncertainty by careful engineering, restore certainty whenever it is lost, reduce the uncertainty by using more accurate sensors, and quantify and circumscribe the remaining uncertainty. Unfortunately, these methods focus exclusively on the sources of uncertainty and fail to apply knowledge of the tasks which are to be scheduled. A complete solution must adapt the schedule of activities to be performed according to the evolving state of the production world. The example of vision-directed assembly is presented to illustrate that the principle of least commitment, in the creation of a plan, in the representation of a schedule, and in the execution of a schedule, enables a robot to operate intelligently and efficiently, even in the presence of considerable uncertainty in the sequence of future events.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge