Hyung-il Ahn

Generative Probabilistic Planning for Optimizing Supply Chain Networks

Apr 11, 2024

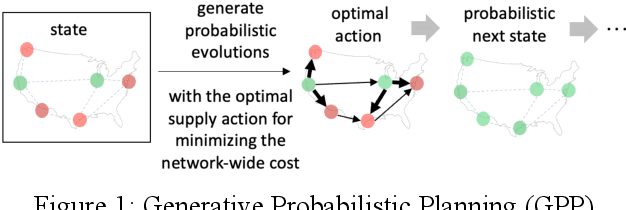

Abstract:Supply chain networks in enterprises are typically composed of complex topological graphs involving various types of nodes and edges, accommodating numerous products with considerable demand and supply variability. However, as supply chain networks expand in size and complexity, traditional supply chain planning methods (e.g., those found in heuristic rule-based and operations research-based systems) tend to become locally optimal or lack computational scalability, resulting in substantial imbalances between supply and demand across nodes in the network. This paper introduces a novel Generative AI technique, which we call Generative Probabilistic Planning (GPP). GPP generates dynamic supply action plans that are globally optimized across all network nodes over the time horizon for changing objectives like maximizing profits or service levels, factoring in time-varying probabilistic demand, lead time, and production conditions. GPP leverages attention-based graph neural networks (GNN), offline deep reinforcement learning (Offline RL), and policy simulations to train generative policy models and create optimal plans through probabilistic simulations, effectively accounting for various uncertainties. Our experiments using historical data from a global consumer goods company with complex supply chain networks demonstrate that GPP accomplishes objective-adaptable, probabilistically resilient, and dynamic planning for supply chain networks, leading to significant improvements in performance and profitability for enterprises. Our work plays a pivotal role in shaping the trajectory of AI adoption within the supply chain domain.

GNN-based Probabilistic Supply and Inventory Predictions in Supply Chain Networks

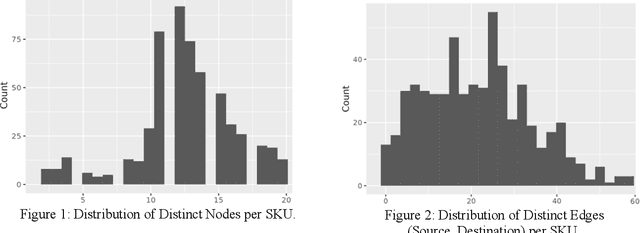

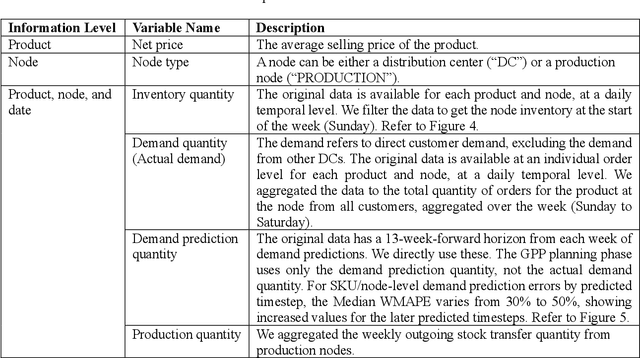

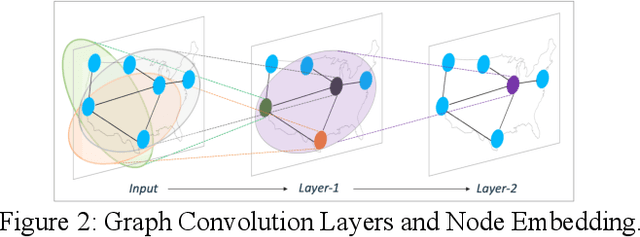

Apr 11, 2024Abstract:Successful supply chain optimization must mitigate imbalances between supply and demand over time. While accurate demand prediction is essential for supply planning, it alone does not suffice. The key to successful supply planning for optimal and viable execution lies in maximizing predictability for both demand and supply throughout an execution horizon. Therefore, enhancing the accuracy of supply predictions is imperative to create an attainable supply plan that matches demand without overstocking or understocking. However, in complex supply chain networks with numerous nodes and edges, accurate supply predictions are challenging due to dynamic node interactions, cascading supply delays, resource availability, production and logistic capabilities. Consequently, supply executions often deviate from their initial plans. To address this, we present the Graph-based Supply Prediction (GSP) probabilistic model. Our attention-based graph neural network (GNN) model predicts supplies, inventory, and imbalances using graph-structured historical data, demand forecasting, and original supply plan inputs. The experiments, conducted using historical data from a global consumer goods company's large-scale supply chain, demonstrate that GSP significantly improves supply and inventory prediction accuracy, potentially offering supply plan corrections to optimize executions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge