Hyun Joon Kim

Small Distance Increment Method for Measuring Complex Permittivity With mmWave Radar

Mar 19, 2024

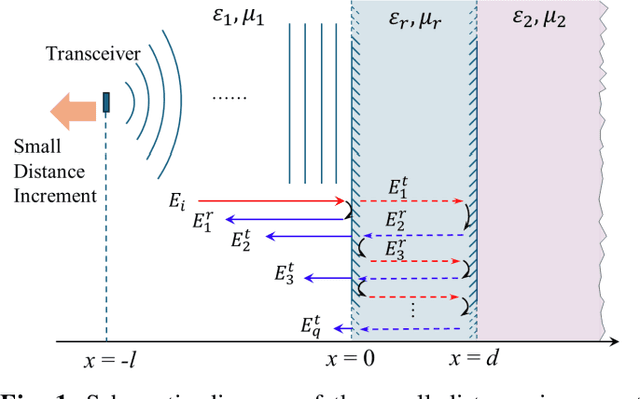

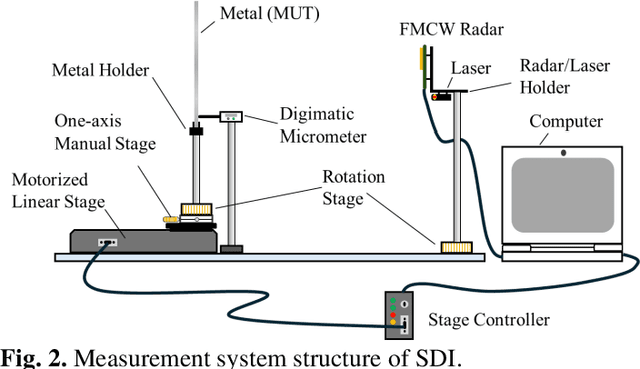

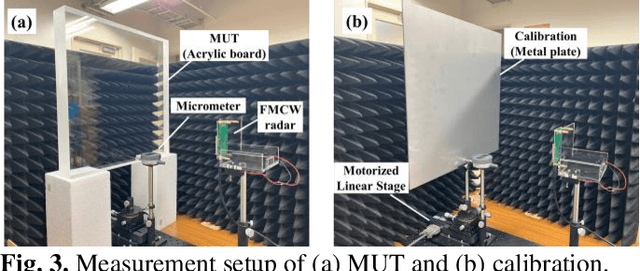

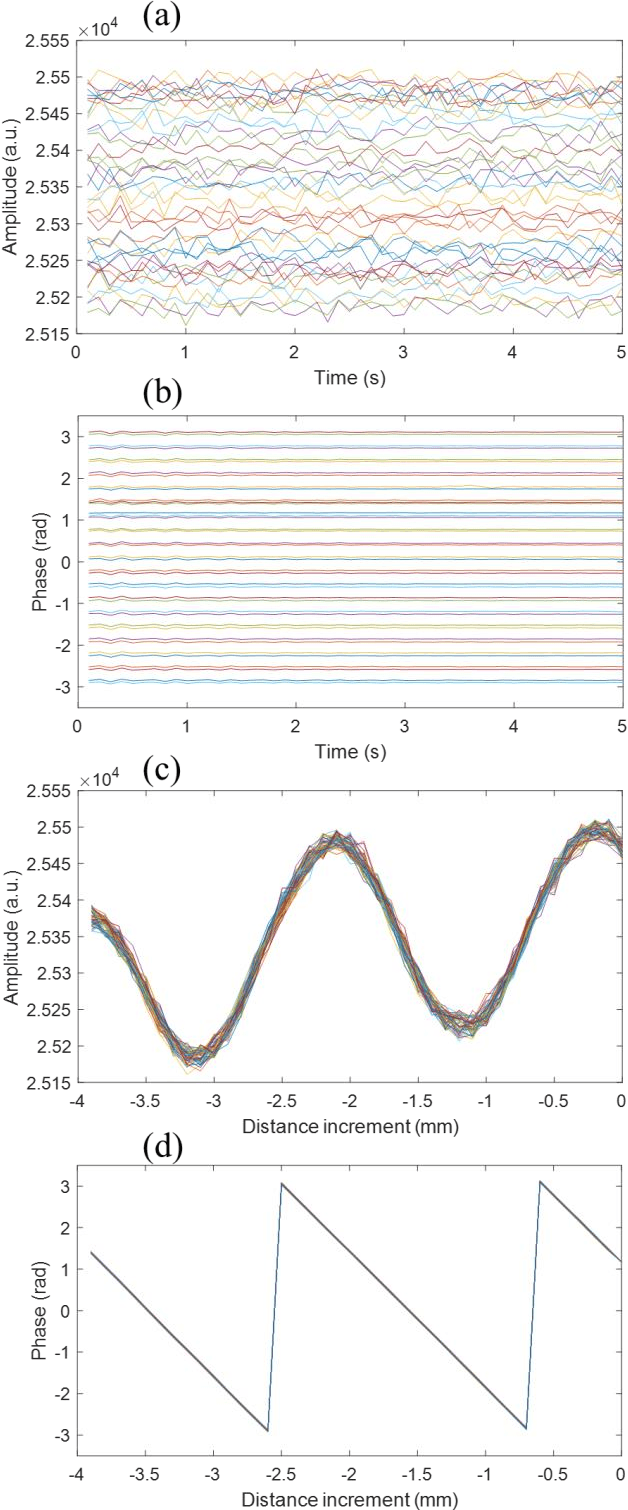

Abstract:Measuring the complex permittivity of material is essential in many scenarios such as quality check and component analysis. Generally, measurement methods for characterizing the material are based on the usage of vector network analyzer, which is large and not easy for on-site measurement, especially in high frequency range such as millimeter wave (mmWave). In addition, some measurement methods require the destruction of samples, which is not suitable for non-destructive inspection. In this work, a small distance increment (SDI) method is proposed to non-destructively measure the complex permittivity of material. In SDI, the transmitter and receiver are formed as the monostatic radar, which is facing towards the material under test (MUT). During the measurement, the distance between radar and MUT changes with small increments and the signals are recorded at each position. A mathematical model is formulated to depict the relationship among the complex permittivity, distance increment, and measured signals. By fitting the model, the complex permittivity of MUT is estimated. To implement and evaluate the proposed SDI method, a commercial off-the-shelf mmWave radar is utilized and the measurement system is developed. Then, the evaluation was carried out on the acrylic plate. With the proposed method, the estimated complex permittivity of acrylic plate shows good agreement with the literature values, demonstrating the efficacy of SDI method for characterizing the complex permittivity of material.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge