Duy-Nhat Phan

Deep Learning-Enhanced for Amine Emission Monitoring and Performance Analysis in Industrial Carbon Capture Plants

Sep 05, 2025Abstract:We present data driven deep learning models for forecasting and monitoring amine emissions and key performance parameters in amine-based post-combustion carbon capture systems. Using operational data from the CESAR1 solvent campaign at Technology Center Mongstad, four DL architectures such as Basic Long Short-Term Memory (LSTM), Stacked LSTM, Bi-directional LSTM, and Convolutional LSTM were developed to capture time-dependent process behavior. For emission prediction, models were designed for 2-amino-2-methyl-1-propanol (AMP) and Piperazine emissions measured via FTIR and IMR-MS methods. System performance models target four critical parameters: CO$_2$ product flow, absorber outlet temperature, depleted flue gas outlet temperature, and RFCC stripper bottom temperature. These models achieved high predictive accuracy exceeding 99% and effectively tracked both steady trends and abrupt fluctuations. Additionally, we conducted causal impact analysis to evaluate how operational variables influence emissions and system performance. Eight input variables were systematically perturbed within $\pm$20% of nominal values to simulate deviations and assess their impact. This analysis revealed that adjusting specific operational parameters, such as lean solvent temperature and water wash conditions, can significantly reduce amine emissions and enhance system performance. This study highlights ML not only as a predictive tool but also as a decision support system for optimizing carbon capture operations under steady state and dynamic conditions. By enabling real time monitoring, scenario testing, and operational optimization, the developed ML framework offers a practical pathway for mitigating environmental impacts. This work represents a step toward intelligent, data-driven control strategies that enhance the efficiency, stability, and sustainability of carbon capture and storage technologies.

Advanced Predictive Quality Assessment for Ultrasonic Additive Manufacturing with Deep Learning Model

Oct 31, 2024

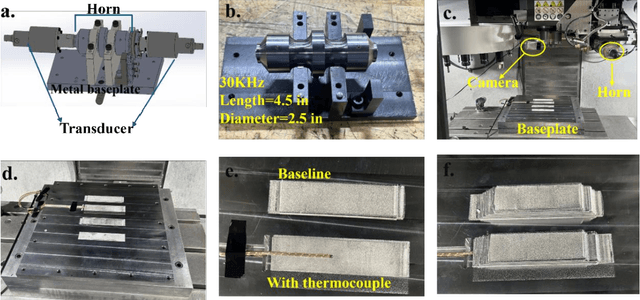

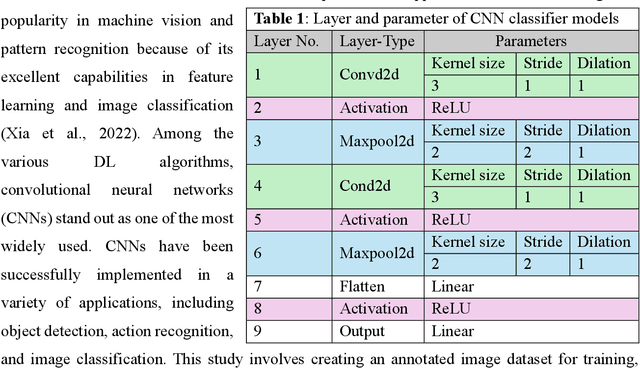

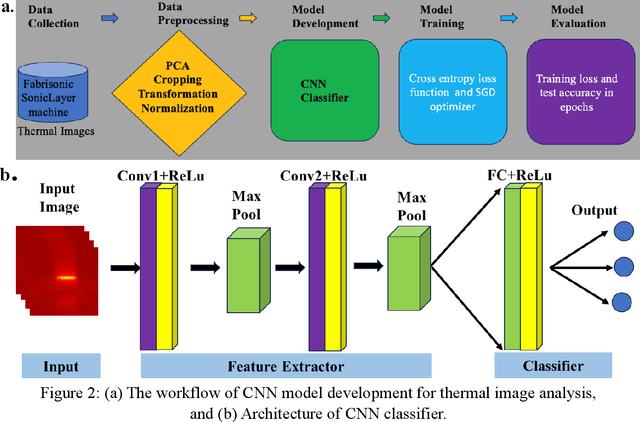

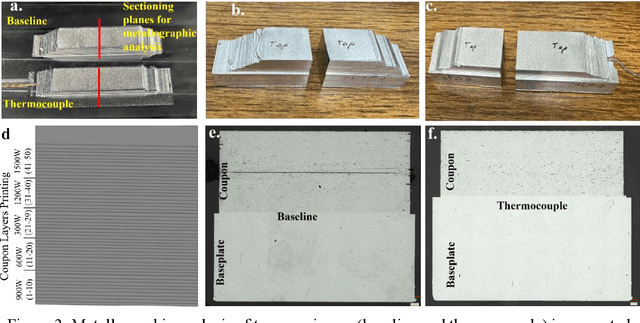

Abstract:Ultrasonic Additive Manufacturing (UAM) employs ultrasonic welding to bond similar or dissimilar metal foils to a substrate, resulting in solid, consolidated metal components. However, certain processing conditions can lead to inter-layer defects, affecting the final product's quality. This study develops a method to monitor in-process quality using deep learning-based convolutional neural networks (CNNs). The CNN models were evaluated on their ability to classify samples with and without embedded thermocouples across five power levels (300W, 600W, 900W, 1200W, 1500W) using thermal images with supervised labeling. Four distinct CNN classification models were created for different scenarios including without (baseline) and with thermocouples, only without thermocouples across power levels, only with thermocouples across power levels, and combined without and with thermocouples across power levels. The models achieved 98.29% accuracy on combined baseline and thermocouple images, 97.10% for baseline images across power levels, 97.43% for thermocouple images, and 97.27% for both types across power levels. The high accuracy, above 97%, demonstrates the system's effectiveness in identifying and classifying conditions within the UAM process, providing a reliable tool for quality assurance and process control in manufacturing environments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge