David J. Braun

Design of a Variable Stiffness Spring with Human-Selectable Stiffness

Feb 27, 2023Abstract:Springs are commonly used in wearable robotic devices to provide assistive joint torque without the need for motors and batteries. However, different tasks (such as walking or running) and different users (such as athletes with strong legs or the elderly with weak legs) necessitate different assistive joint torques, and therefore, springs with different stiffness. Variable stiffness springs are a special class of springs which can exert more or less torque upon the same deflection, provided that the user is able to change the stiffness of the spring. In this paper, we present a novel variable stiffness spring design in which the user can select a preferred spring stiffness similar to switching gears on a bicycle. Using a leg-swing experiment, we demonstrate that the user can increment and decrement spring stiffness in a large range to effectively assist the hip joint during leg oscillations. Variable stiffness springs with human-selectable stiffness could be key components of wearable devices which augment locomotion tasks, such as walking, running, and swimming.

Controllable Mechanical-domain Energy Accumulators

Dec 29, 2022

Abstract:Springs are efficient in storing and returning elastic potential energy but are unable to hold the energy they store in the absence of an external load. Lockable springs use clutches to hold elastic potential energy in the absence of an external load but have not yet been widely adopted in applications, partly because clutches introduce design complexity, reduce energy efficiency, and typically do not afford high-fidelity control over the energy stored by the spring. Here, we present the design of a novel lockable compression spring that uses a small capstan clutch to passively lock a mechanical spring. The capstan clutch can lock up to 1000 N force at any arbitrary deflection, unlock the spring in less than 10 ms with a control force less than 1 % of the maximal spring force, and provide an 80 % energy storage and return efficiency (comparable to a highly efficient electric motor operated at constant nominal speed). By retaining the form factor of a regular spring while providing high-fidelity locking capability even under large spring forces, the proposed design could facilitate the development of energy-efficient spring-based actuators and robots.

Novel Spring Mechanism Enables Iterative Energy Accumulation under Force and Deformation Constraints

Dec 29, 2022Abstract:Springs can provide force at zero net energy cost by recycling negative mechanical work to benefit motor-driven robots or spring-augmented humans. However, humans have limited force and range of motion, and motors have a limited ability to produce force. These limits constrain how much energy a conventional spring can store and, consequently, how much assistance a spring can provide. In this paper, we introduce an approach to accumulating negative work in assistive springs over several motion cycles. We show that, by utilizing a novel floating spring mechanism, the weight of a human or robot can be used to iteratively increase spring compression, irrespective of the potential energy stored by the spring. Decoupling the force required to compress a spring from the energy stored by a spring advances prior works, and could enable spring-driven robots and humans to perform physically demanding tasks without the use of large actuators.

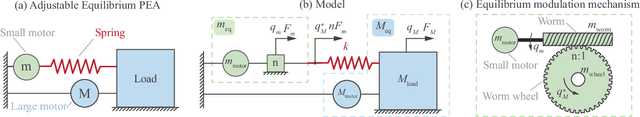

Design of a Parallel Elastic Actuator with a Continuously-Adjustable Equilibrium Position

Dec 15, 2022

Abstract:In this paper, we present an adjustable-equilibrium parallel elastic actuator (AE-PEA). The actuator consists of a motor, an equilibrium adjusting mechanism, and a spring arranged into a cylindrical geometry, similar to a motor-gearbox assembly. The novel component of the actuator is the equilibrium adjusting mechanism which (i) does not require external energy to maintain the equilibrium position of the actuator even if the spring is deformed and (ii) enables equilibrium position control with low energy cost by rotating the spring while keeping it undeformed. Adjustable equilibrium parallel elastic actuators resolve the main limitation of parallel elastic actuators (PEAs) by enabling energy-efficient operation at different equilibrium positions, instead of being limited to energy-efficient operation at a single equilibrium position. We foresee the use of AE-PEAs in industrial robots, mobile robots, exoskeletons, and prostheses, where efficient oscillatory motion and gravity compensation at different positions are required.

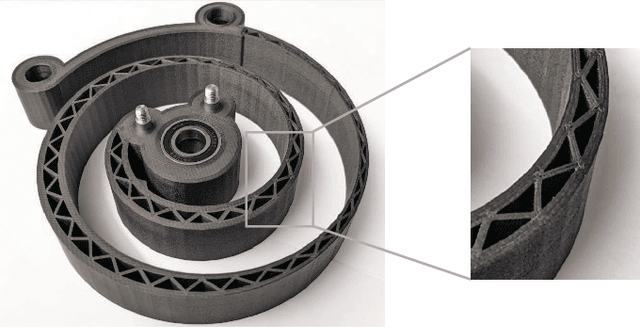

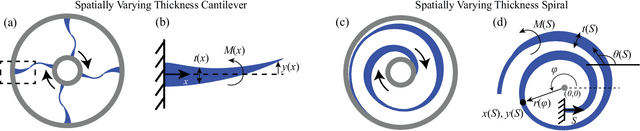

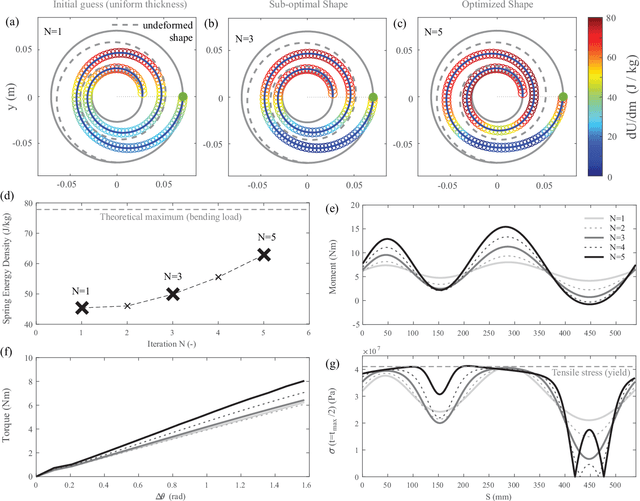

High-energy-density 3D-printed Composite Springs for Lightweight and Energy-efficient Compliant Robots

Nov 16, 2022

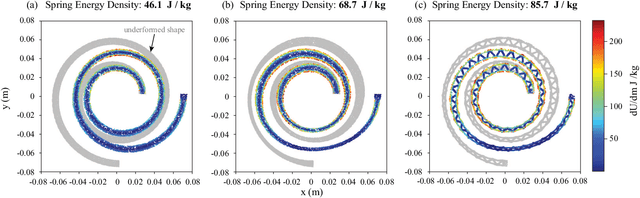

Abstract:Springs store mechanical energy similar to batteries storing electrical energy. However, conventional springs are heavy and store limited amounts of mechanical energy relative to batteries, i.e they have low mass-energy-density. Next-generation 3D printing technology could potentially enable manufacturing low cost lightweight springs with high energy storage capacity. Here we present a novel design of a high-energy-density 3D printed torsional spiral spring using structural optimization. By optimizing the internal structure of the spring we obtained a 45% increase in the mass energy density, compared to a torsional spiral spring of uniform thickness. Our result suggests that optimally designed 3D printed springs could enable robots to recycle more mechanical energy per unit mass, potentially reducing the energy required to control robots.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge