Cedric Schockaert

A Causal-based Framework for Multimodal Multivariate Time Series Validation Enhanced by Unsupervised Deep Learning as an Enabler for Industry 4.0

Aug 05, 2020

Abstract:An advanced conceptual validation framework for multimodal multivariate time series defines a multi-level contextual anomaly detection ranging from an univariate context definition, to a multimodal abstract context representation learnt by an Autoencoder from heterogeneous data (images, time series, sounds, etc.) associated to an industrial process. Each level of the framework is either applicable to historical data and/or live data. The ultimate level is based on causal discovery to identify causal relations in observational data in order to exclude biased data to train machine learning models and provide means to the domain expert to discover unknown causal relations in the underlying process represented by the data sample. A Long Short-Term Memory Autoencoder is successfully evaluated on multivariate time series to validate the learnt representation of abstract contexts associated to multiple assets of a blast furnace. A research roadmap is identified to combine causal discovery and representation learning as an enabler for unsupervised Root Cause Analysis applied to the process industry.

MTS-CycleGAN: An Adversarial-based Deep Mapping Learning Network for Multivariate Time Series Domain Adaptation Applied to the Ironmaking Industry

Jul 15, 2020

Abstract:In the current era, an increasing number of machine learning models is generated for the automation of industrial processes. To that end, machine learning models are trained using historical data of each single asset leading to the development of asset-based models. To elevate machine learning models to a higher level of learning capability, domain adaptation has opened the door for extracting relevant patterns from several assets combined together. In this research we are focusing on translating the specific asset-based historical data (source domain) into data corresponding to one reference asset (target domain), leading to the creation of a multi-assets global dataset required for training domain invariant generic machine learning models. This research is conducted to apply domain adaptation to the ironmaking industry, and particularly for the creation of a domain invariant dataset by gathering data from different blast furnaces. The blast furnace data is characterized by multivariate time series. Domain adaptation for multivariate time series data hasn't been covered extensively in the literature. We propose MTS-CycleGAN, an algorithm for Multivariate Time Series data based on CycleGAN. To the best of our knowledge, this is the first time CycleGAN is applied on multivariate time series data. Our contribution is the integration in the CycleGAN architecture of a Long Short-Term Memory (LSTM)-based AutoEncoder (AE) for the generator and a stacked LSTM-based discriminator, together with dedicated extended features extraction mechanisms. MTS-CycleGAN is validated using two artificial datasets embedding the complex temporal relations between variables reflecting the blast furnace process. MTS-CycleGAN is successfully learning the mapping between both artificial multivariate time series datasets, allowing an efficient translation from a source to a target artificial blast furnace dataset.

Attention Mechanism for Multivariate Time Series Recurrent Model Interpretability Applied to the Ironmaking Industry

Jul 15, 2020

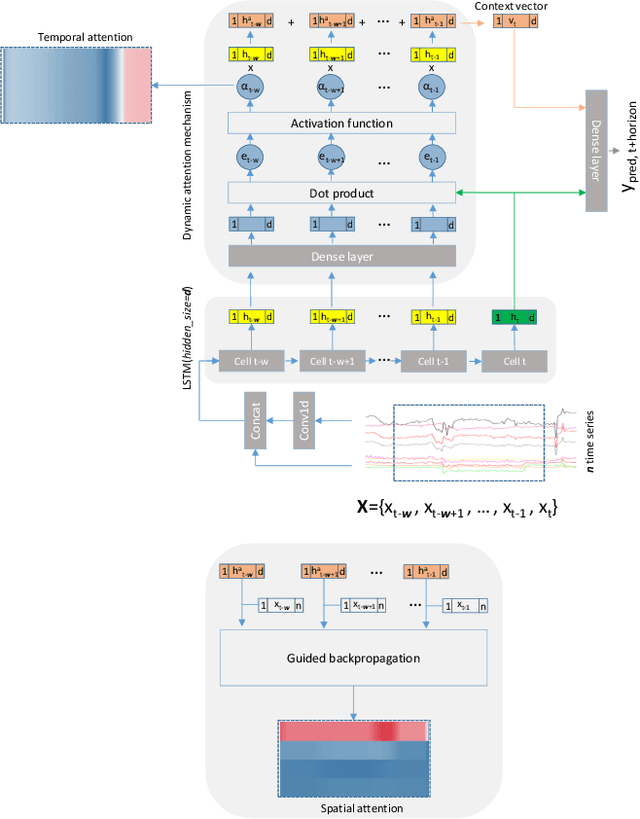

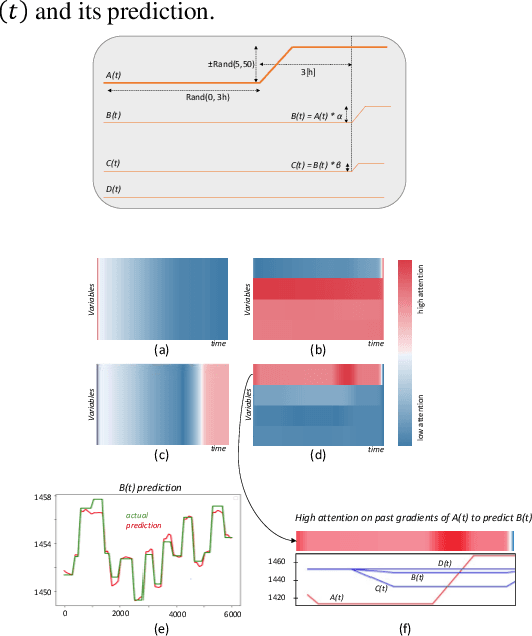

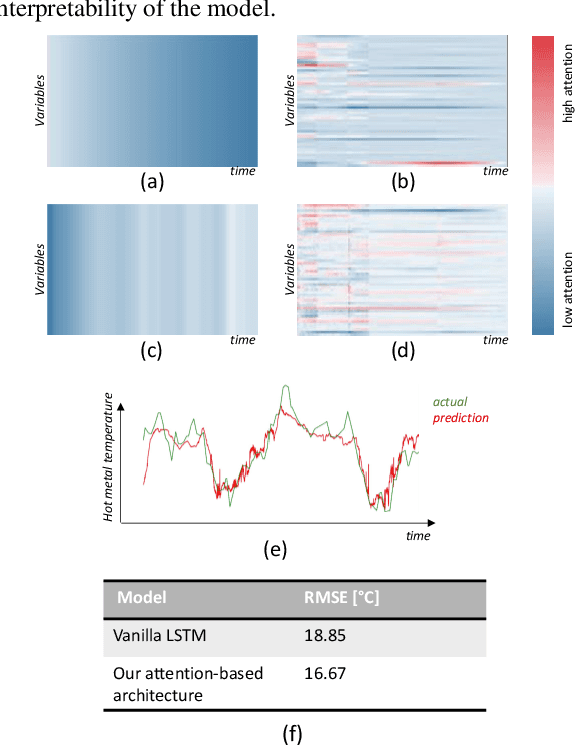

Abstract:Data-driven model interpretability is a requirement to gain the acceptance of process engineers to rely on the prediction of a data-driven model to regulate industrial processes in the ironmaking industry. In the research presented in this paper, we focus on the development of an interpretable multivariate time series forecasting deep learning architecture for the temperature of the hot metal produced by a blast furnace. A Long Short-Term Memory (LSTM) based architecture enhanced with attention mechanism and guided backpropagation is proposed to accommodate the prediction with a local temporal interpretability for each input. Results are showing high potential for this architecture applied to blast furnace data and providing interpretability correctly reflecting the true complex variables relations dictated by the inherent blast furnace process, and with reduced prediction error compared to a recurrent-based deep learning architecture.

VAE-LIME: Deep Generative Model Based Approach for Local Data-Driven Model Interpretability Applied to the Ironmaking Industry

Jul 15, 2020

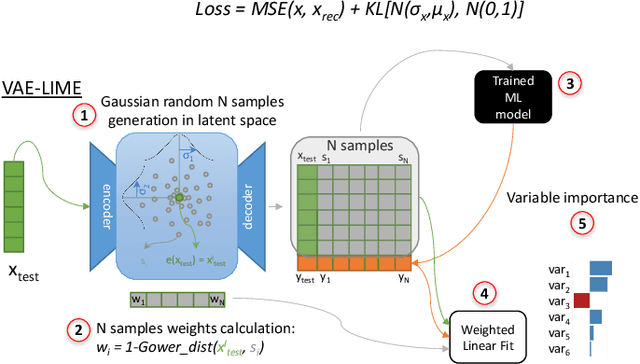

Abstract:Machine learning applied to generate data-driven models are lacking of transparency leading the process engineer to lose confidence in relying on the model predictions to optimize his industrial process. Bringing processes in the industry to a certain level of autonomy using data-driven models is particularly challenging as the first user of those models, is the expert in the process with often decades of experience. It is necessary to expose to the process engineer, not solely the model predictions, but also their interpretability. To that end, several approaches have been proposed in the literature. The Local Interpretable Model-agnostic Explanations (LIME) method has gained a lot of interest from the research community recently. The principle of this method is to train a linear model that is locally approximating the black-box model, by generating randomly artificial data points locally. Model-agnostic local interpretability solutions based on LIME have recently emerged to improve the original method. We present in this paper a novel approach, VAE-LIME, for local interpretability of data-driven models forecasting the temperature of the hot metal produced by a blast furnace. Such ironmaking process data is characterized by multivariate time series with high inter-correlation representing the underlying process in a blast furnace. Our contribution is to use a Variational Autoencoder (VAE) to learn the complex blast furnace process characteristics from the data. The VAE is aiming at generating optimal artificial samples to train a local interpretable model better representing the black-box model in the neighborhood of the input sample processed by the black-box model to make a prediction. In comparison with LIME, VAE-LIME is showing a significantly improved local fidelity of the local interpretable linear model with the black-box model resulting in robust model interpretability.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge