Ahmad Amer

Gaussian Process Regression for Active Sensing Probabilistic Structural Health Monitoring: Experimental Assessment Across Multiple Damage and Loading Scenarios

Jun 28, 2021

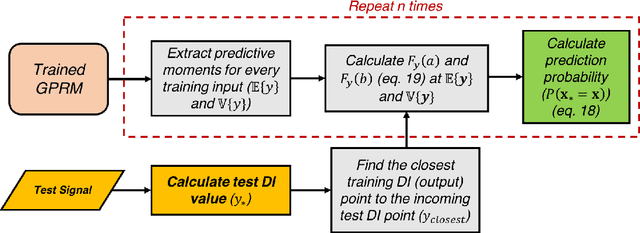

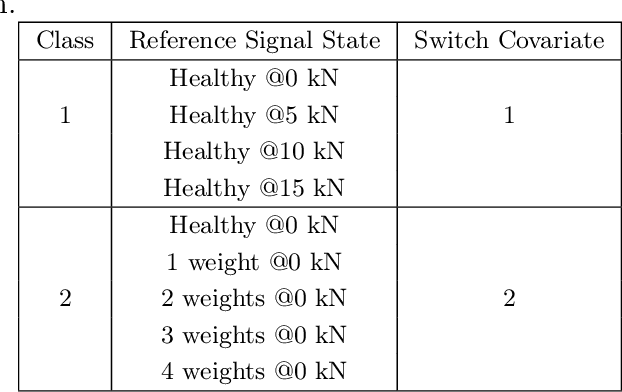

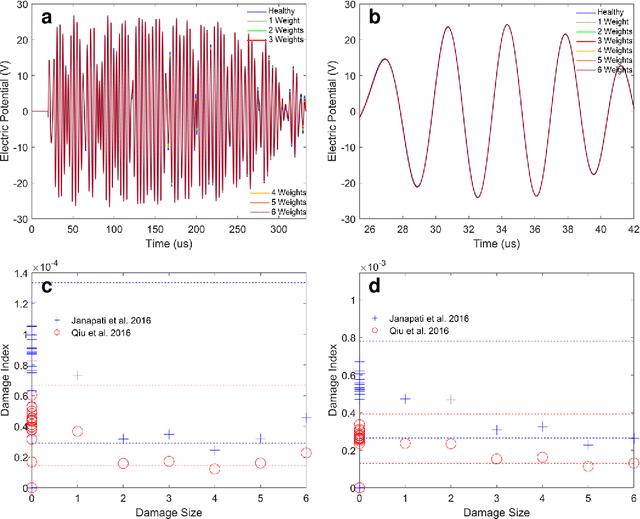

Abstract:In the near future, Structural Health Monitoring (SHM) technologies will be capable of overcoming the drawbacks in the current maintenance and life-cycle management paradigms, namely: cost, increased downtime, less-than-optimal safety management paradigm and the limited applicability of fully-autonomous operations. In the context of SHM, one of the most challenging tasks is damage quantification. Current methods face accuracy and/or robustness issues when it comes to varying operating and environmental conditions. In addition, the damage/no-damage paradigm of current frameworks does not offer much information to maintainers on the ground for proper decision-making. In this study, a novel structural damage quantification framework is proposed based on widely-used Damage Indices (DIs) and Gaussian Process Regression Models (GPRMs). The novelty lies in calculating the probability of an incoming test DI point originating from a specific state, which allows for probability-educated decision-making. This framework is applied to three test cases: a Carbon Fiber-Reinforced Plastic (CFRP) coupon with attached weights as simulated damage, an aluminum coupon with a notch, and an aluminum coupon with attached weights as simulated damage under varying loading states. The state prediction method presented herein is applied to single-state quantification in the first two test cases, as well as the third one assuming the loading state is known. Finally, the proposed method is applied to the third test case assuming neither the damage size nor the load is known in order to predict both simultaneously from incoming DI test points. In applying this framework, two forms of GPRMs (standard and variational heteroscedastic) are used in order to critically assess their performances with respect to the three test cases.

Statistical guided-waves-based SHM via stochastic non-parametric time series models

Jan 29, 2021

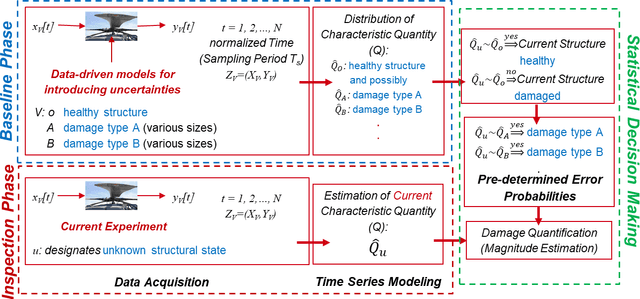

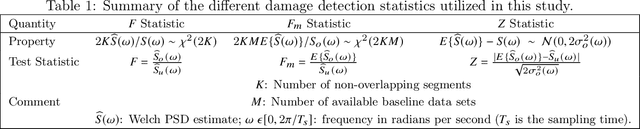

Abstract:Damage detection in active-sensing, guided-waves-based Structural Health Monitoring (SHM) has evolved through multiple eras of development during the past decades. Nevertheless, there still exists a number of challenges facing the current state-of-the-art approaches, both in the industry as well as in research and development, including low damage sensitivity, lack of robustness to uncertainties, need for user-defined thresholds, and non-uniform response across a sensor network. In this work, a novel statistical framework is proposed for active-sensing SHM based on the use of ultrasonic guided waves. This framework is based on stochastic non-parametric time series models and their corresponding statistical properties in order to readily provide healthy confidence bounds and enable accurate and robust damage detection via the use of appropriate statistical decision making tests. Three such methods and corresponding statistical quantities (test statistics) along with decision making schemes are formulated and experimentally assessed via the use of three coupons with different levels of complexity: an Al plate with a growing notch, a Carbon fiber-reinforced plastic (CFRP) plate with added weights to simulate local damages, and the CFRP panel used in the Open Guided Waves project [1], all fitted with piezoelectric transducers and a pitch-catch configuration. The performance of the proposed methods is compared to that of state-of-the-art time-domain damage indices (DIs). The results demonstrate the increased sensitivity and robustness of the proposed methods, with better tracking capability of damage evolution compared to conventional approaches, even for damage-non-intersecting actuator-sensor paths. Overall, the proposed statistical methods exhibit greater damage sensitivity across different components, with enhanced robustness to uncertainty, as well as user-friendly application.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge