Solving Mixed Model Workplace Time-dependent Assembly Line Balancing Problem with FSS Algorithm

Paper and Code

Jul 19, 2017

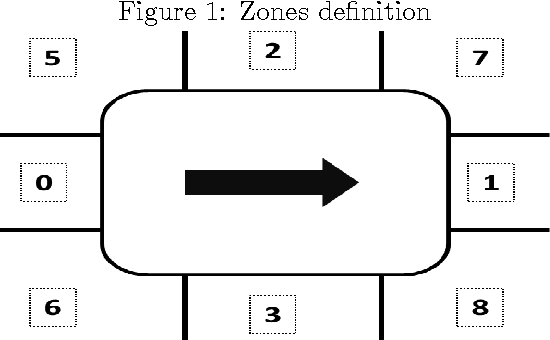

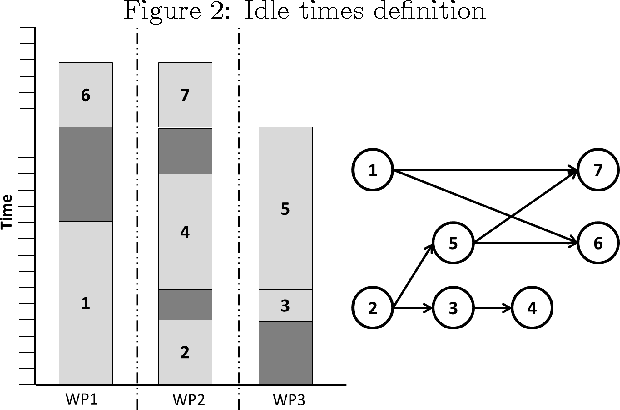

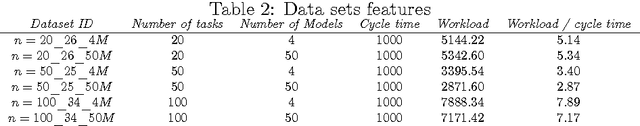

Balancing assembly lines, a family of optimization problems commonly known as Assembly Line Balancing Problem, is notoriously NP-Hard. They comprise a set of problems of enormous practical interest to manufacturing industry due to the relevant frequency of this type of production paradigm. For this reason, many researchers on Computational Intelligence and Industrial Engineering have been conceiving algorithms for tackling different versions of assembly line balancing problems utilizing different methodologies. In this article, it was proposed a problem version referred as Mixed Model Workplace Time-dependent Assembly Line Balancing Problem with the intention of including pressing issues of real assembly lines in the optimization problem, to which four versions were conceived. Heuristic search procedures were used, namely two Swarm Intelligence algorithms from the Fish School Search family: the original version, named "vanilla", and a special variation including a stagnation avoidance routine. Either approaches solved the newly posed problem achieving good results when compared to Particle Swarm Optimization algorithm.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge