Preprocessing and Modeling of Radial Fan Data for Health State Prediction

Paper and Code

Sep 08, 2021

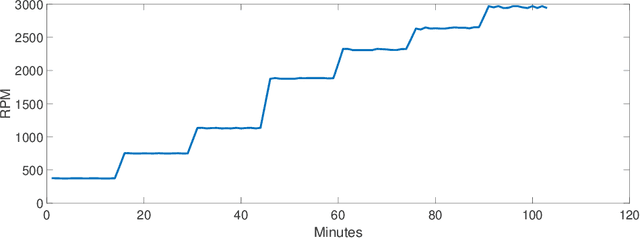

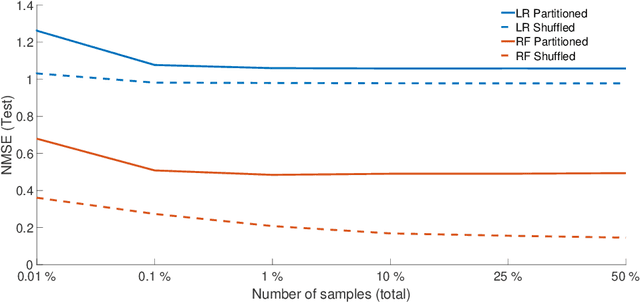

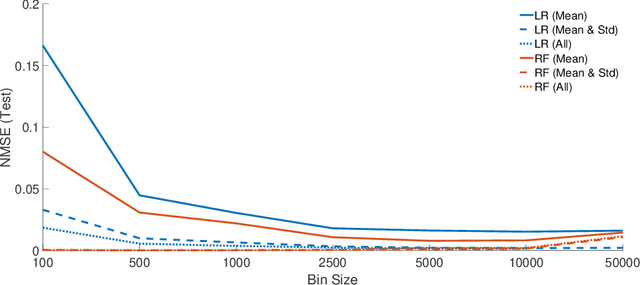

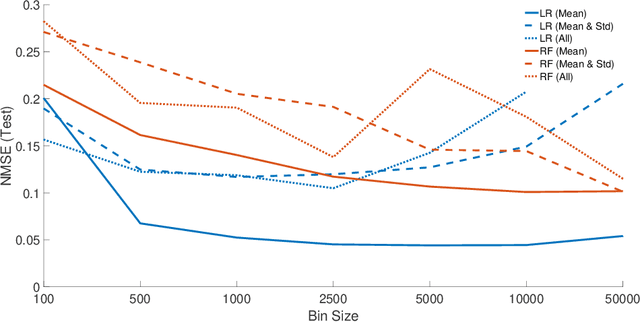

Monitoring critical components of systems is a crucial step towards failure safety. Affordable sensors are available and the industry is in the process of introducing and extending monitoring solutions to improve product quality. Often, no expertise of how much data is required for a certain task (e.g. monitoring) exists. Especially in vital machinery, a trend to exaggerated sensors may be noticed, both in quality and in quantity. This often results in an excessive generation of data, which should be transferred, processed and stored nonetheless. In a previous case study, several sensors have been mounted on a healthy radial fan, which was later artificially damaged. The gathered data was used for modeling (and therefore monitoring) a healthy state. The models were evaluated on a dataset created by using a faulty impeller. This paper focuses on the reduction of this data through downsampling and binning. Different models are created with linear regression and random forest regression and the resulting difference in quality is discussed.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge