One-class Steel Detector Using Patch GAN Discriminator for Visualising Anomalous Feature Map

Paper and Code

Jun 30, 2021

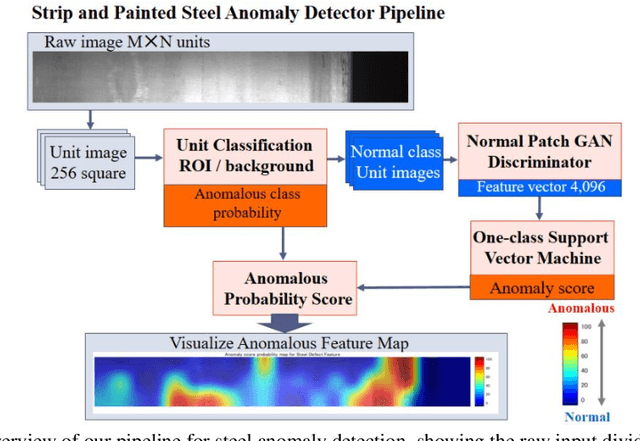

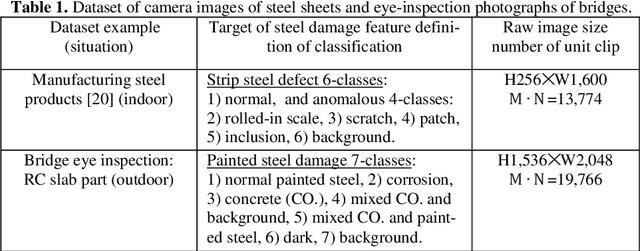

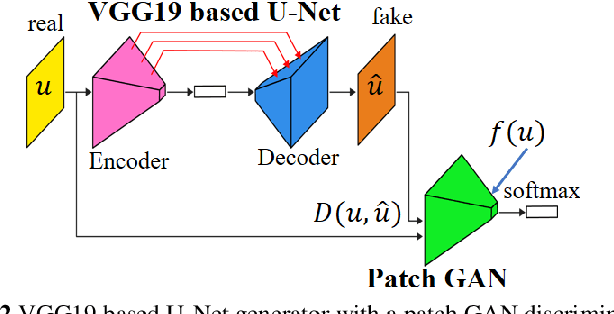

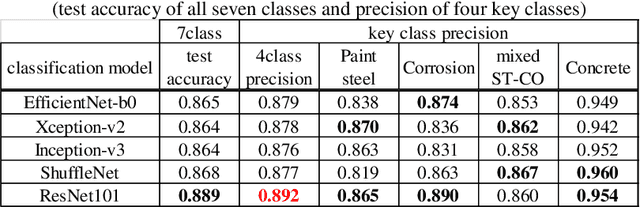

For steel product manufacturing in indoor factories, steel defect detection is important for quality control. For example, a steel sheet is extremely delicate, and must be accurately inspected. However, to maintain the painted steel parts of the infrastructure around a severe outdoor environment, corrosion detection is critical for predictive maintenance. In this paper, we propose a general-purpose application for steel anomaly detection that consists of the following four components. The first, a learner, is a unit image classification network to determine whether the region of interest or background has been recognised, after dividing the original large sized image into 256 square unit images. The second, an extractor, is a discriminator feature encoder based on a pre-trained steel generator with a patch generative adversarial network discriminator(GAN). The third, an anomaly detector, is a one-class support vector machine(SVM) to predict the anomaly score using the discriminator feature. The fourth, an indicator, is an anomalous probability map used to visually explain the anomalous features. Furthermore, we demonstrated our method through the inspection of steel sheet defects with 13,774 unit images using high-speed cameras, and painted steel corrosion with 19,766 unit images based on an eye inspection of the photographs. Finally, we visualise anomalous feature maps of steel using a strip and painted steel inspection dataset

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge