Multi-objective optimization of actuation waveform for high-precision drop-on-demand inkjet printing

Paper and Code

Aug 24, 2022

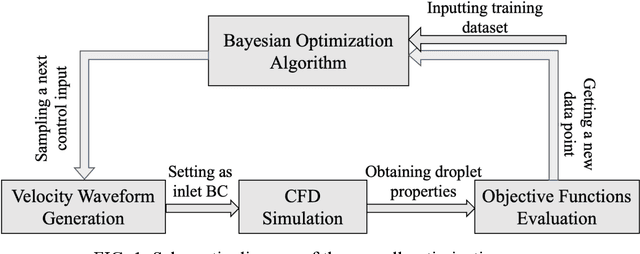

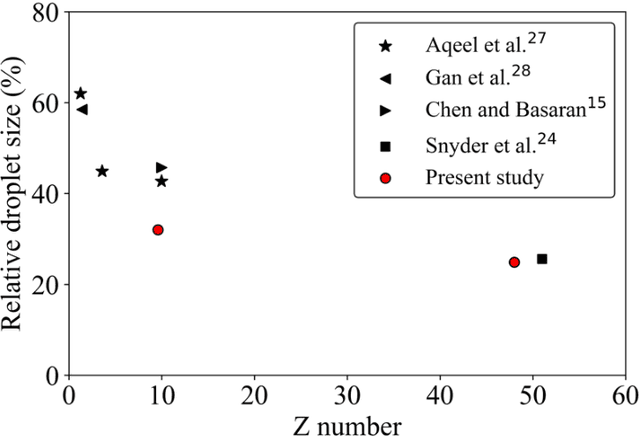

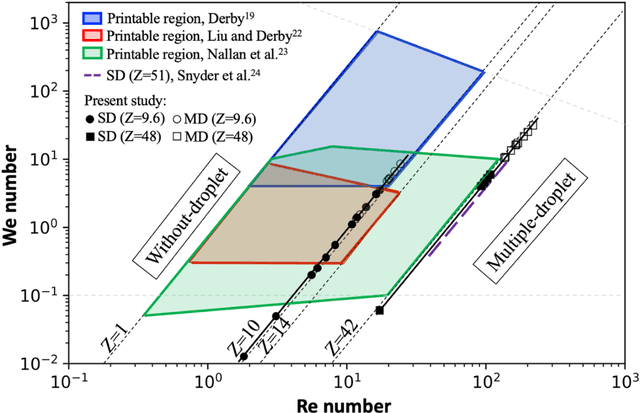

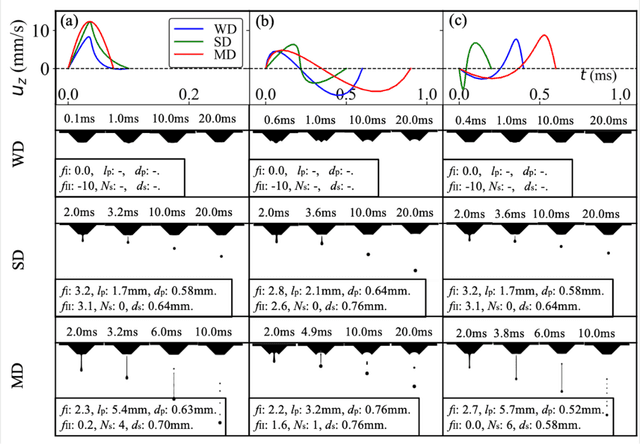

Drop-on-demand (DOD) inkjet printing has been considered as one of promising technologies for the fabrication of advanced functional materials. For a DOD printer, high-precision dispensing techniques for achieving satellite-free smaller droplets, have long been desired for patterning thin-film structures. The present study considers the inlet velocity of a liquid chamber located upstream of a dispensing nozzle as a control variable and aims to optimize its waveform using a sample-efficient Bayesian optimization algorithm. Firstly, the droplet dispensing dynamics are numerically reproduced by using an open-source OpenFOAM solver, interFoam, and the results are passed on to another code based on pyFoam. Then, the parameters characterizing the actuation waveform driving a DOD printer are determined by the Bayesian optimization (BO) algorithm so as to maximize a prescribed multi-objective function expressed as the sum of two factors, i.e., the size of a primary droplet and the presence of satellite droplets. The results show that the present BO algorithm can successfully find high-precision dispensing waveforms within 150 simulations. Specifically, satellite droplets can be effectively eliminated and the droplet diameter can be significantly reduced to 24.9% of the nozzle diameter by applying the optimal waveform.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge