Minimizing Robot Digging Times to Retrieve Bins in Robotic-Based Compact Storage and Retrieval Systems

Paper and Code

Dec 08, 2023

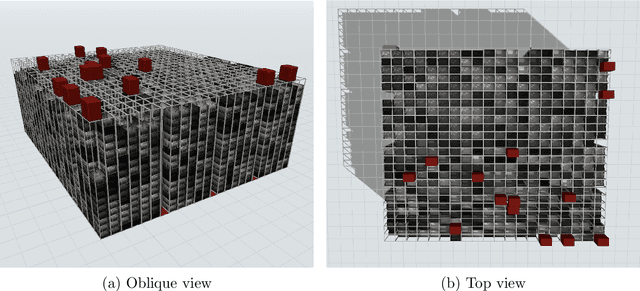

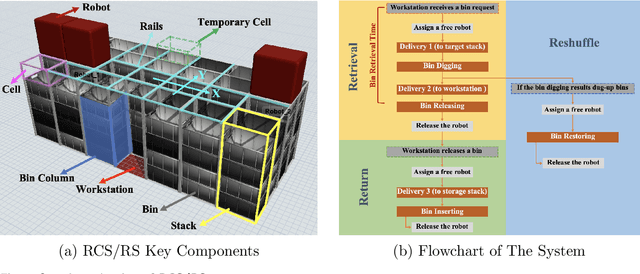

Robotic-based compact storage and retrieval systems provide high-density storage in distribution center and warehouse applications. In the system, items are stored in bins, and the bins are organized inside a three-dimensional grid. Robots move on top of the grid to retrieve and deliver bins. To retrieve a bin, a robot removes all bins above one by one with its gripper, called bin digging. The closer the target bin is to the top of the grid, the less digging is required to retrieve the bin. In this paper, we propose a policy to optimally arrange the bins in the grid while processing bin requests so that the most frequently accessed bins remain near the top of the grid. This improves the performance of the system and makes it responsive to changes in bin demand. Our solution approach identifies the optimal bin arrangement in the storage facility, initiates a transition to this optimal set-up, and subsequently ensures the ongoing maintenance of this arrangement for optimal performance. We perform extensive simulations on a custom-built discrete event model of the system. Our simulation results show that under the proposed policy more than half of the bins requested are located on top of the grid, reducing bin digging compared to existing policies. Compared to existing approaches, the proposed policy reduces the retrieval time of the requested bins by over 30% and the number of bin requests that exceed certain time thresholds by nearly 50%.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge