Defect Localization Using Region of Interest and Histogram-Based Enhancement Approaches in 3D-Printing

Paper and Code

Apr 25, 2024

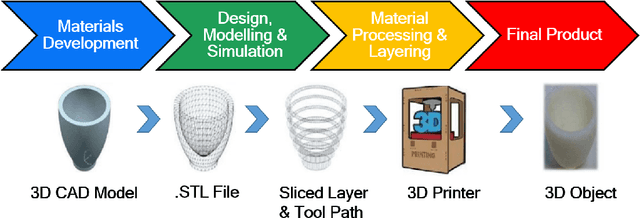

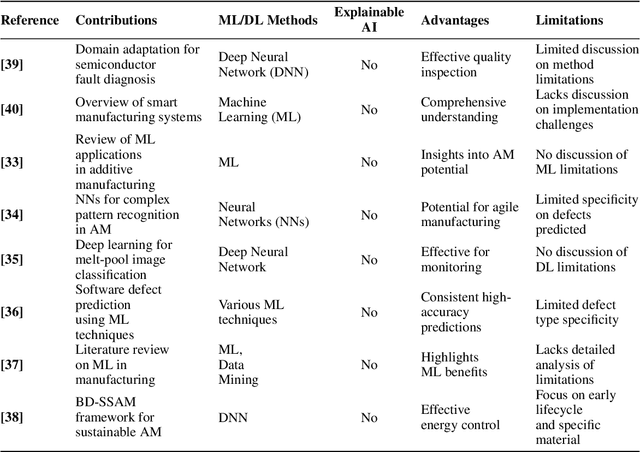

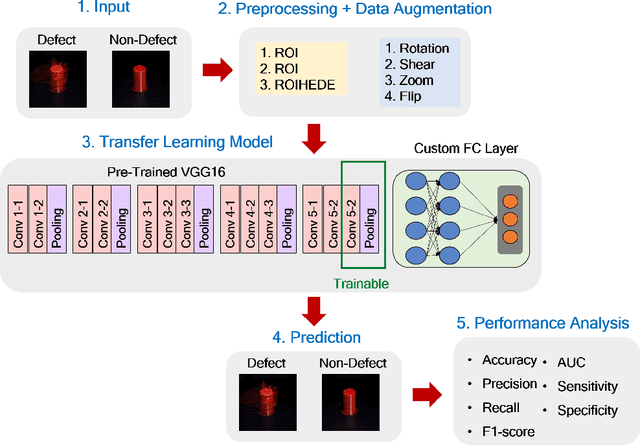

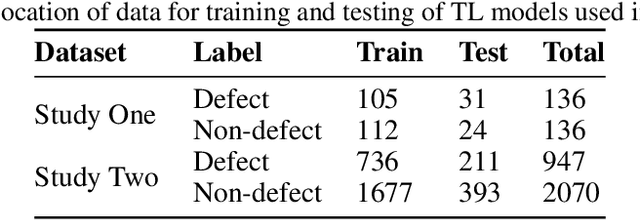

Additive manufacturing (AM), particularly 3D printing, has revolutionized the production of complex structures across various industries. However, ensuring quality and detecting defects in 3D-printed objects remain significant challenges. This study focuses on improving defect detection in 3D-printed cylinders by integrating novel pre-processing techniques such as Region of Interest (ROI) selection, Histogram Equalization (HE), and Details Enhancer (DE) with Convolutional Neural Networks (CNNs), specifically the modified VGG16 model. The approaches, ROIN, ROIHEN, and ROIHEDEN, demonstrated promising results, with the best model achieving an accuracy of 1.00 and an F1-score of 1.00 on the test set. The study also explored the models' interpretability through Local Interpretable Model-Agnostic Explanations and Gradient-weighted Class Activation Mapping, enhancing the understanding of the decision-making process. Furthermore, the modified VGG16 model showed superior computational efficiency with 30713M FLOPs and 15M parameters, the lowest among the compared models. These findings underscore the significance of tailored pre-processing and CNNs in enhancing defect detection in AM, offering a pathway to improve manufacturing precision and efficiency. This research not only contributes to the advancement of 3D printing technology but also highlights the potential of integrating machine learning with AM for superior quality control.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge