Deep learning models for predictive maintenance: a survey, comparison, challenges and prospect

Paper and Code

Oct 07, 2020

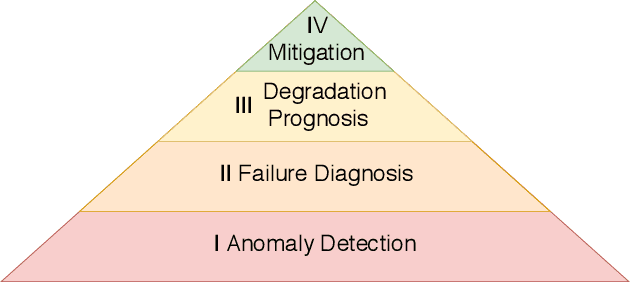

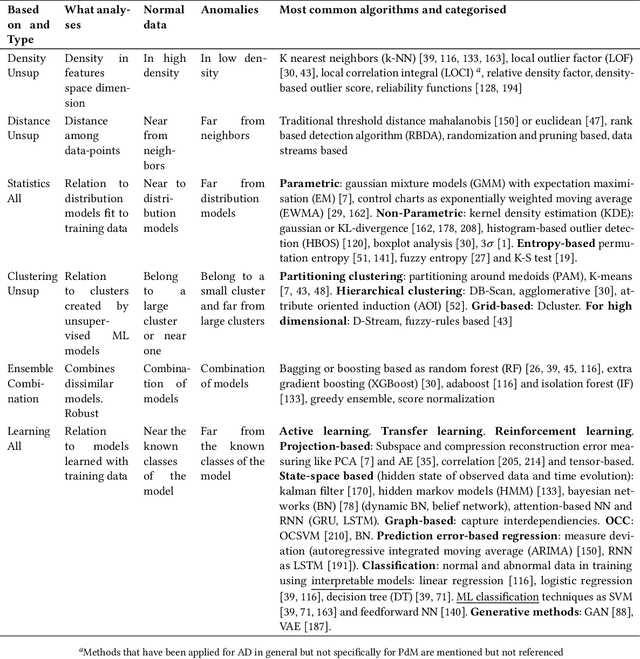

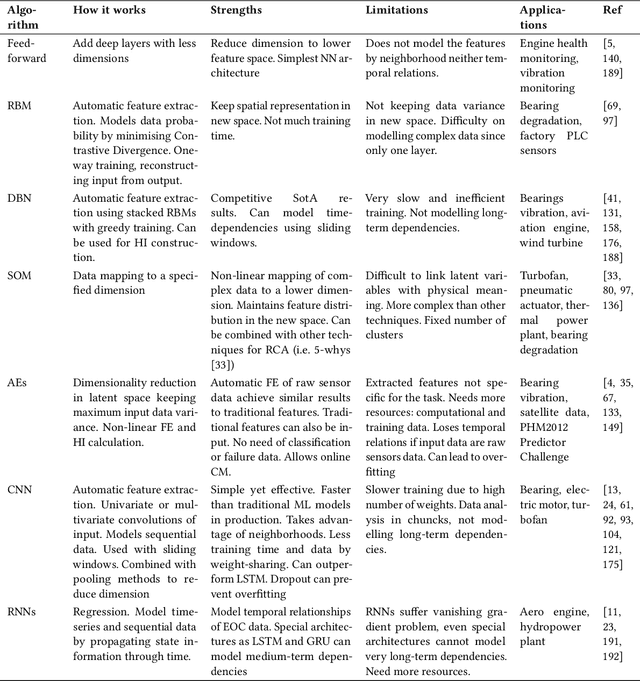

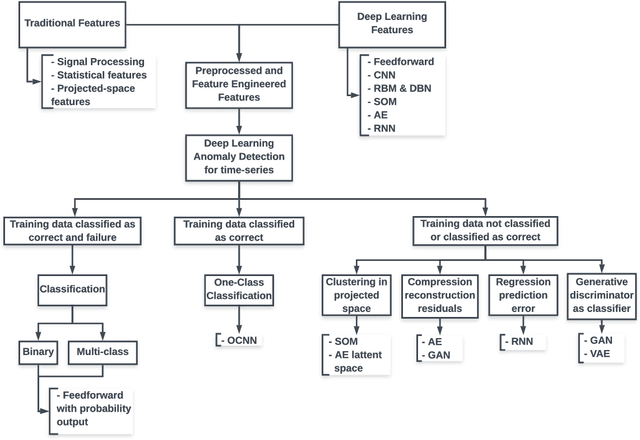

Given the growing amount of industrial data spaces worldwide, deep learning solutions have become popular for predictive maintenance, which monitor assets to optimise maintenance tasks. Choosing the most suitable architecture for each use-case is complex given the number of examples found in literature. This work aims at facilitating this task by reviewing state-of-the-art deep learning architectures, and how they integrate with predictive maintenance stages to meet industrial companies' requirements (i.e. anomaly detection, root cause analysis, remaining useful life estimation). They are categorised and compared in industrial applications, explaining how to fill their gaps. Finally, open challenges and future research paths are presented.

* 34 pages, 214 references, 8 tables, 2 equations, 2 figures, survey

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge