Computer Vision based Tomography of Structures Using 3D Digital Image Correlation

Paper and Code

Dec 18, 2020

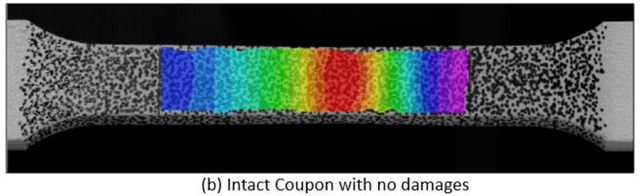

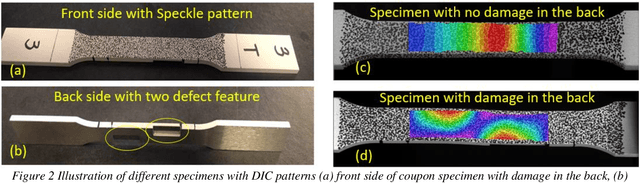

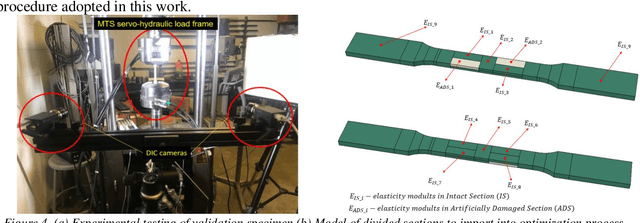

Internal properties of a sample can be observed by medical imaging tools, such as ultrasound devices, magnetic resonance imaging (MRI) and optical coherence tomography (OCT) which are based on relying on changes in material density or chemical composition [1-21]. As a preliminary investigation, the feasibility to detect interior defects inferred from the discrepancy in elasticity modulus distribution of a three-dimensional heterogeneous sample using only surface full-field measurements and finite element model updating as an inverse optimization algorithm without any assumption about local homogeneities and also the elasticity modulus distribution is investigated. Recently, the authors took advantages of the digital image correlation technique as a full field measurement in constitutive property identification of a full-scale steel component [22-27]. To the extension of previous works, in this brief technical note, the new idea intended at recovering unseen volumetric defect distributions within the interior of three-dimensional heterogeneous space of the structural component using 3D-Digital Image Correlation for structural identification [28-57]. As a proof of concept, the results of this paper illustrate the potential to identify invisible internal defect by the proposed computer vision technique establishes the potential for new opportunities to characterize internal heterogeneous materials for their mechanical property distribution and condition state.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge