A simulated annealing approach to optimal storing in a multi-level warehouse

Paper and Code

Mar 25, 2017

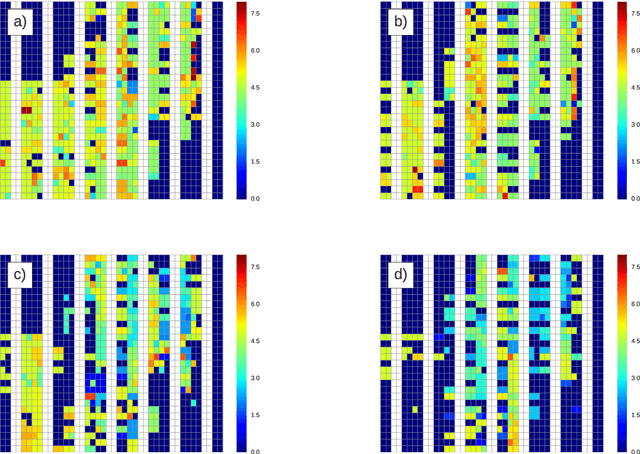

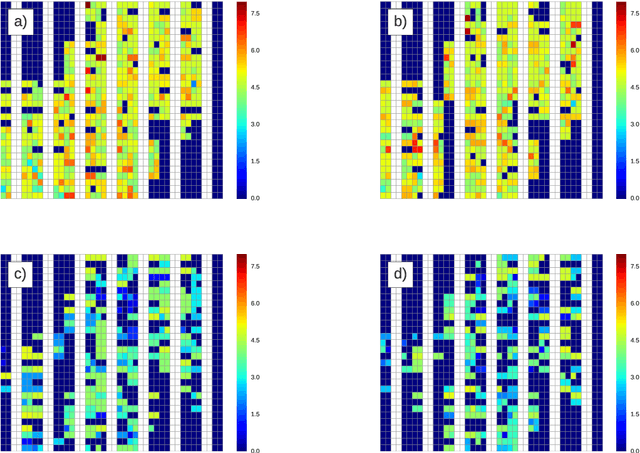

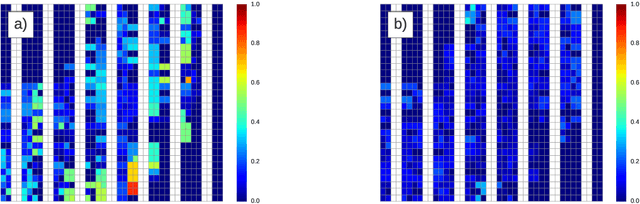

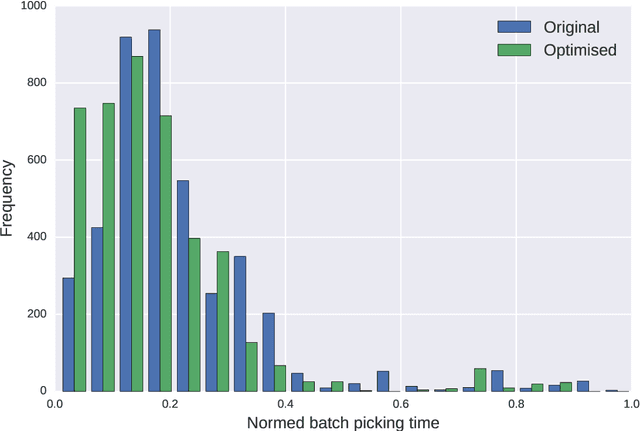

We propose a simulated annealing algorithm specifically tailored to optimise total retrieval times in a multi-level warehouse under complex pre-batched picking constraints. Experiments on real data from a picker-to-parts order picking process in the warehouse of a European manufacturer show that optimal storage assignments do not necessarily display features presumed in heuristics, such as clustering of positively correlated items or ordering of items by picking frequency. In an experiment run on more than 4000 batched orders with 1 to 150 items per batch, the storage assignment suggested by the algorithm produces a 21\% reduction in the total retrieval time with respect to a frequency-based storage assignment.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge